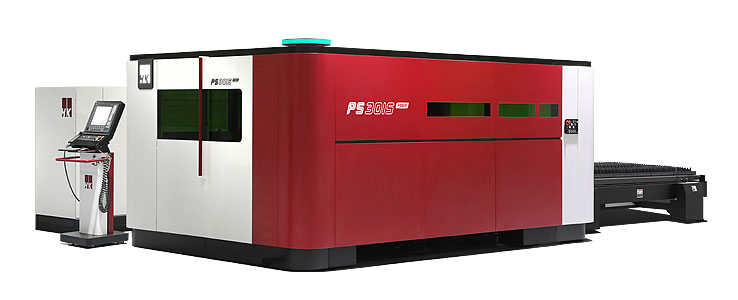

Tci Cutting Waterjet & Laser Systems

High energy density spots are formed by focusing the laser beam's energies. The medium and extended focusing lens are suitable for thick plates cutting. It also has very low spacing stability requirements. The shorter focusing lens is best suited for thin sheets cutting. This requires high spacing stability of the tracking systems and greatly reduces output power requirements.

The work-life of this machine is around 1,00,000 hours. This machine can both, mark and engrave and that too with high precision. The design is plug-and-play and requires almost no consumables. The price range of this industrial fiber laser marking machine varies from 5000 USD to 9000 USD.